|

|

|

GRS 180

Beside the press granulator

8.5" X 11" cutting chamber

Runners and smaller parts

Low RPM

Less than 10 minute complete material change

GRS 300

Beside the press granulator

14.5" X 17.5" cutting chamber

Runners and medium size parts

Low RPM

Less than 10 minute complete material change

MEETS YOUR APPLICATION NEEDS

Whether the need is picker fed, beside the press granulators or batch

feed granulators of parts and runners, the GRS series deliver what plastics

manufacturers have been seeking for years; excellent regrind quality,

low maintenance and operating costs, and a wide window of operation.

| The GRS series is a continuation of the ARG angled rotor granulator series that

has been highly successful in the United States and worldwide, selling over 25,000

units since its inception.

The new GRS series continues the tradition of Getecha's proprietary angled rotor design with either 7 or 10 blade rotors. The special angled rotor design, maximum cuts per revolution, low rotor revolution (200 RPM standard) and continuous cutting circle combine to assure an excellent quality regrind with low fines and a highly consistent particle size, even with highly filled engineered materials.

|

GRS 300, 7.5 HP, 14.5" X 17.5" cutting chamber |

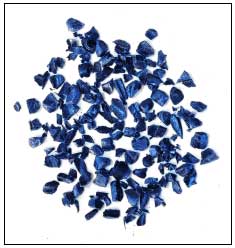

BETTER REGRIND

The design of the angled rotor, coupled with the slow rotor speed provides the optimal combination of factors to provide the best regrind you can get from a granulator - bar none! In side-by-side, customer located granulator tests, the Getecha GRS granulators have time and again outperformed our competitors units - hands down with fewer fines, more consistent particle size, elimination of longs.

Regrind with Getecha GRS Granulator GRS 180 6mm angled screen |

Regrind from other granulator brand competitors unit with 0.25" screen |

MANY MATERIALS - ONE SERIES

The GRS Series is used throughout the world for a variety of materials. From the softer Santoprenes to extremely high filled (65%+) materials, and everything in between! You no longer need different granulators for different materials.

|

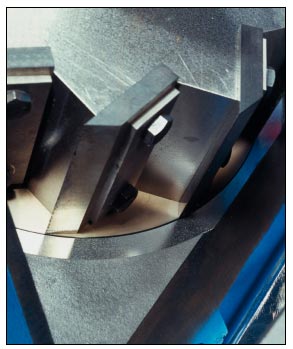

FMC - 10 MINUTES

The GRS series launches Getecha's divided, drop-down cutting chamber (see photo) that provides immediate, tool-free access to the rotor, hopper, screen and entire cutting chamber. This feature provides for incredibly fast black to white clean-out times of 5-10 minutes. This feature dove tails perfectly with the demands of today's quick material change applications and lean manufacturing practices.

|

NO LONGS OR OVERS

The GRS series granulators also include the popular optional system for the elimination of longs or "thrues", even with runners as small as an eighth of an inch in diameter. Ask you sales person for more details about this sub $300 option.

ROTATING ROTOR END PLATE

| The GRS series offers as standard rotating rotor end plate. By turning the end plate with the rotor, the trapping of material between the two is no longer possible. Trapped material results in several negative effects: shortens the life of the unit, mills harder materials to dust, smears softer materials for regrind and heat degradation, makes full clean-outs next to impossible.

Eliminate your problems with a rotating rotor end plate and start realizing the benefits of better quality regrind! End plate turns with rotor.

|

|

WEAR AND TEAR THAT MAKES SENSE

The very affordable wear and tear option makes long-lasting sense. What you get:

1. 64 Rockwell through hardened (re-sharpenable) rotary blades made from HSS steel

2. 64 Rockwell through hardened (re-sharpenable) bed knives with welded in tips

3. Hardened screen

4. Hardened pre-cutter

5. Hardened rotating rotor end plate

Other wear packages available for hardened hoppers and discharge devices based on extreme customer needs.

A MAINTENANCE DREAM COME TRUE

The GRS series is a dream for maintenance

departments with its virtually maintenance

free design. With the exception of changing

or sharpening blades (with new blades being

self-setting), the unit can be placed into

operation and virtually forgotten about for

five or more years. There are no lubrication

points and the incorporated self-tensioning

belt device (see photo) eliminates the

constant need for re-tensioning belts on

others granulators. The sealed bearings combined with a rotating, flush mounted rotor endplate virtually eliminate potential bearing issues.

The result is an overall savings of actual maintenance time on a per unit basis versus competing units. Less labor, lower costs, reasonably priced spare parts means a more profitable granulator.

|

|

MANY CONFIGURATIONS TO MEET YOUR SPECIFIC NEEDS

The GRS granulator series can be configured to meet your individual needs.

Hopper varieties, including custom built to your application/plant

Discharge devices

Variable speeds and motor sizes (some application dependant)

Screens

Rotor configurations

Machine stands

Magnets (for hopper and discharge)

Infeed systems

CUSTOMER COMMENTS

ACM Southwest Web Testimonial (Adobe PDF)

Jergens Innovative Technology Testimonial (Adobe PDF)

Philidelphia Plastics Testimonial (Adobe PDF)

|