|

|

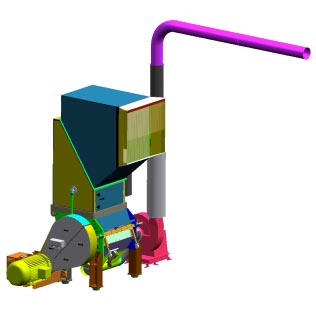

Getecha RS 8000 Series Super Heavy Duty Granulators

The RS 8000 Series represents Getecha largest, standard model-line granulator. While we do build larger granulators with rotors exceeding 36" in diameter, the largest units are built on a special application basis only.

The RS 8000 Series Granulators are designed for applications requiring the best built, most heavy-duty granulators for particularly demanding applications.

| Common applications: |

Recycling

Central granulation

High throughput application

Bulky, voluminous parts granulating

Heavy duty parts granulating |

Main Features:

Individual machine adjustment by modular design

Hopper

Rotor

Cutting chamber

Machine base/frame

Optimal accessibility for cleaning and servicing

|

Hydraulically activated hopper with side access door (tool free operation)

Hydraulically activated screen cradle (tool free operation)

Fully removable screen cradle on casters (tool free operation)

|

Screen cradle rolled out from under cutting chamber |

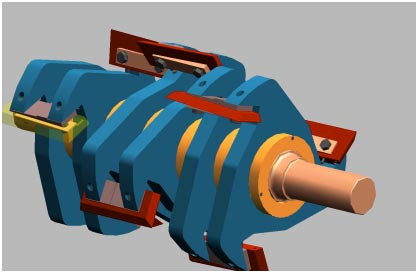

Superior rotor design

Segmented rotor for lengthened blade life (standard)

Off-rotor blade setting fixture for fastest blade changes (standard)

12" length blades for easy and safe blade handling (standard)

Staggered design for optimally cutting efficiency, reduced horsepower, better regrind and quieter operation (depending on application - no upcharge)

Multi-blade rotor configurations (3, 5, 7, 9)

Individually replaceable rotor segments (standard)

Various rotor designs depending on the application

Reverse mounted blade design (optional, application dependent)

|

Cutting build design

Massive pulley/flywheel for reduced energy consumption and stable operation (standard)

Rotor bearings positioned outside the cutting chamber for longevity and easy of access (standard)

Optional 3rd bed knife for special applications (application dependent option)

Scissors cut for better regrind and cutting efficiency (standard)

Continuous cutting radius for consistent performance (standard)

Split screens for easier handling (standard)

Split evacuation material container for more consistent removal of regrind (standard)

|

|

Controls and electronics

Control panel incorporates controls for granulator, evacuation system, hydraulic system (standard)

Smart relay with fault reporting screen for identifying potential fault conditions (standard)

Self monitoring safety switches to meet new safety requirements

Remote operated handheld control wand (standard, see photo, click on photo to link to full feature description)

All components are integrated as standard into the electronic controls

|

|

|